H.B series gearbox

Gear box product features

Gear

High-precision gear machining, the gear accuracy is AGMA11-12 or DN5-6.

The gear with high wear resistance has a tooth surface hardness of 59+3HRC.

In the design of long-life gears, the bearing life of gears is calculated according to the principle of infinite life design.

The tooth surface and tooth profile are all modified by the leading technology to ensure the lowest noise and efficient transmission.

Heat dispersion

Gear box not only has high transmission efficiency, but also has good heat dissipation performance.

Larger heat dissipation surface area of box body

Optional configuration-large fan and new guide fan cover

Optional configuration-forced lubrication/external cooling

Bearing

Rolling bearings adopt internationally renowned brands.

The thrust bearing adopts modular design, which can be flexibly customized according to customer's needs.

Building block design

The gearbox adopts a new modular unit structure, which greatly reduces the types of parts, resulting in the vast majority of parts in stock, enabling gearboxes around the world to be supplied in a short time.

Shaft seal

The combined seal can prevent dust particles from entering the gearbox and make it output reliably and stably in the dust environment.

Infinite life design

The gear is designed with infinite life, and the service life is longer under the same stress condition.

Gear box design

2.1Determine transmission ratio

i=n1/n2=1500/9≈167

The corresponding nominal speed ratio is 160.

2.2 Determine the rated power of the gearbox

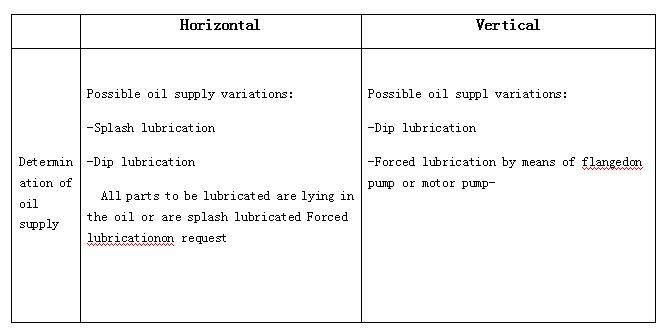

2.3 Determine the layout form

Select orthogonal shaft gearbox according to equipment requirements.

Arrangement A (recommended for counterclockwise rotation of output shaft)

2.4 Determine specifications and models

The rated power of 844KW can meet the requirements, and the model B4SV25A160 is determined.