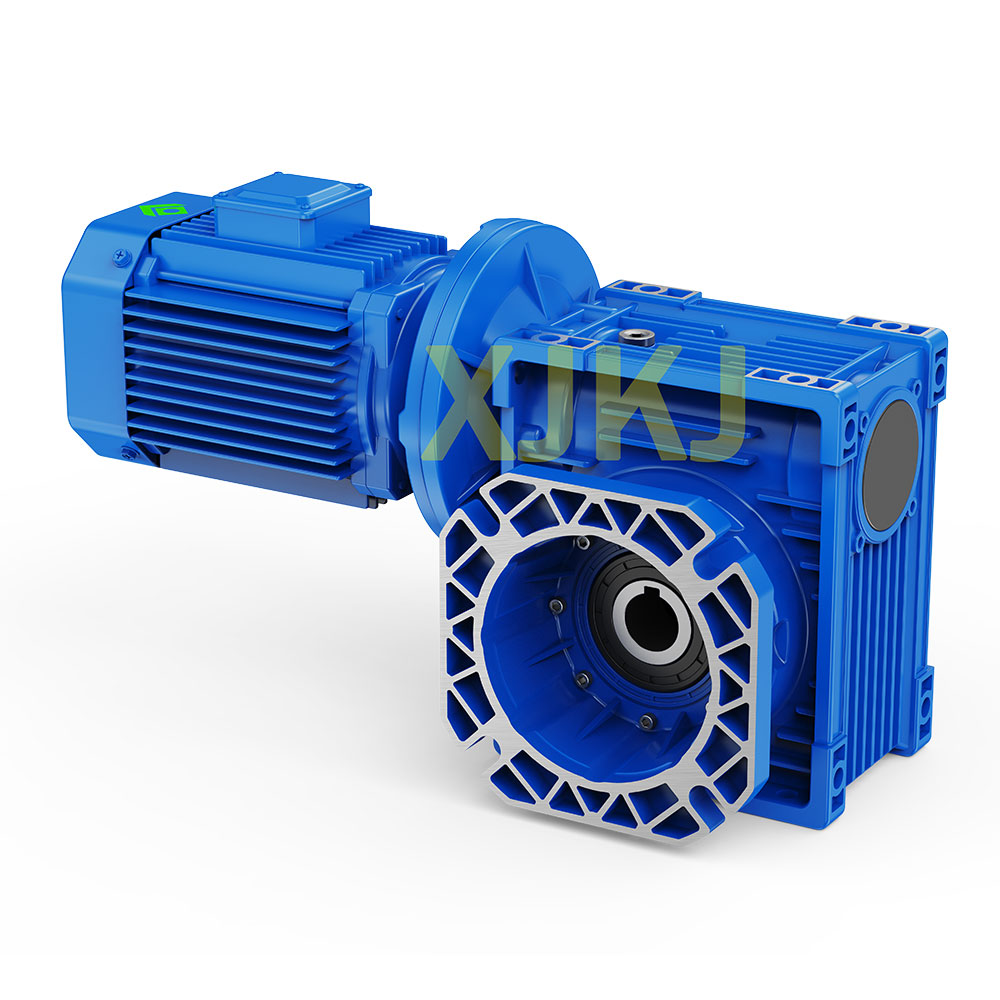

Worm gear and worm reducer

Introduction

Among the mechanisms used to transmit power and motion, the reducer has a wide range of applications. It can be seen in the transmission system of all kinds of machinery, from ships, cars and locomotives, heavy machinery used in construction, processing machinery and automatic production equipment used in machinery industry, to common household appliances, clocks and watches in daily life. Its application can be seen from the transmission of large power to the transmission of small load and precise angle, and in industrial applications, the reducer has the function of slowing down and increasing torque. Therefore, it is widely used in speed and torque conversion equipment.

Structure

The basic structure of XJRV series aluminum alloy worm gear reducer is mainly composed of transmission parts worm gear, shaft, bearing, box and its accessories. It can be divided into three basic structural parts: box, worm gear, bearing and shaft combination. The box is the base of all the accessories in the worm gear reducer, and it is an important accessory to support and fix the shafting components, ensure the correct relative position of the transmission accessories and support the load acting on the reducer. Worm gear and worm are mainly used to transmit the motion and power between two staggered shafts, and bearings and shafts are mainly used to transmit power, run and improve efficiency.

Shell: aluminum alloy (frame: 025-090) and cast iron (frame: 110-150);

Worm: 20Cr steel. Carbonitriding treatment (after fine grinding, the tooth surface hardness HRC60 is maintained, and the hardness thickness is greater than 0.5 mm);

Worm gear: specially configured wear-resistant nickel bronze;

Oil cover/breather: mainly used to exhaust the gas in the gearbox of turbo-worm reducer;

The end cover is divided into a big end cover and a small end cover, the end cover is used for fixing the axial position of the shafting component and bearing the axial load, and both ends of the bearing seat hole are closed by bearing covers;

Oil seal, mainly used to prevent the leakage of lubricating oil inside the chassis and improve the service life of lubricating oil;

Oil drain plug, mainly used for discharging dirty oil and cleaning oil when replacing lubricating oil;

Oil mark cover/oil mark is mainly used to observe whether the oil quantity inside the gearbox of the worm gear reducer reaches the standard.

Features

(1) Compact mechanical structure, light volume and shape, small size and high efficiency;

(2) Good heat exchange performance and fast heat dissipation;

(3) Simple installation, flexibility and lightness, superior performance and easy maintenance;

(4) stable operation, low noise and durability;

(5) Strong usability, safety and reliability;

Classify

Main models: WP series worm gear reducer, WH series worm gear reducer and CW series worm gear reducer, etc.

WP series

Including WPA/WPS/WPW/WPE/WPZ/WPD.

WH series

Including WHT/WHX/WHS/WHC.

CW series

Including CWU/CWS/CWO.

RV series

Including RV/NMRV/NRV.