XJF parallel axis helical gear reducer

Product features

(1)Compact structure: The parallel-axis helical gear reducer adopts gears arranged in parallel axes, which makes the whole device compact in structure and relatively small in occupied space.

(2)High efficiency: The transmission efficiency of the parallel axis helical gear reducer is higher, usually above 95%, which reduces the energy loss.

(3)Strong bearing capacity: The parallel-axis helical gear reducer adopts helical gear transmission, which can bear large torque and load.

(4) Smooth operation: The contact point of the bevel gear of the parallel axis bevel gear reducer is small, and the noise and vibration during transmission are small, so the operation is stable and reliable.

Specification parameters

Installation type: base type, flange type, small flange type and torsion arm type installation.

Output mode: solid shaft, hollow shaft, expansion disc hollow shaft and involute spline hollow shaft output.

Input methods: direct motor, shaft input and connecting flange input.

The basic speed ratio of reduction ratio is 8.1 ~ 191, the XJK/XJR combination can reach 13459, and the average efficiency is 94%.

Working principle

Parallel axis bevel gear reducer is mainly composed of driving shaft, driven shaft, bevel gear and box. When the driving shaft rotates, the driven shaft rotates through the gear to achieve the deceleration effect. The specific working principle is as follows: transmission shaft transmission: the transmission shaft is equipped with a transmission gear. When the transmission shaft rotates, the driving gear drives the helical gear to rotate. Driven shaft transmission: the driven shaft is equipped with a driven gear, and the helical gear drives the driven gear to rotate, thus realizing the rotation of the driven shaft. Deceleration: Because the gear on the driving shaft is larger than the gear on the driven shaft, the deceleration effect can be achieved through gear transmission, thus transforming the high-speed rotation of the driving shaft into low-speed rotation. Driven shaft. Through this working principle, the parallel-axis helical gear reducer realizes the transmission from the high-speed rotation of the driving shaft to the low-speed rotation of the driven shaft, making it suitable for occasions where deceleration is needed.

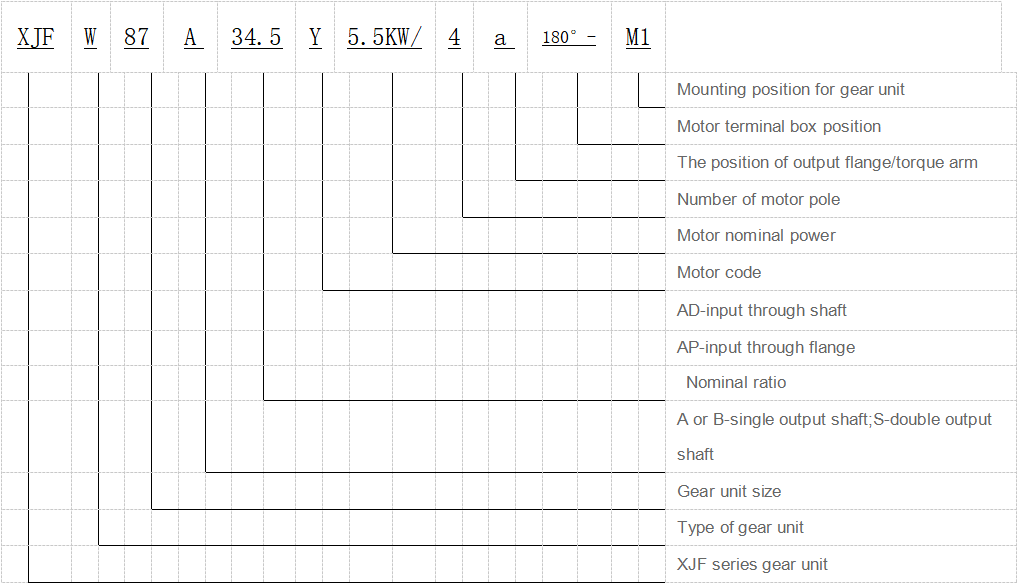

Representation method