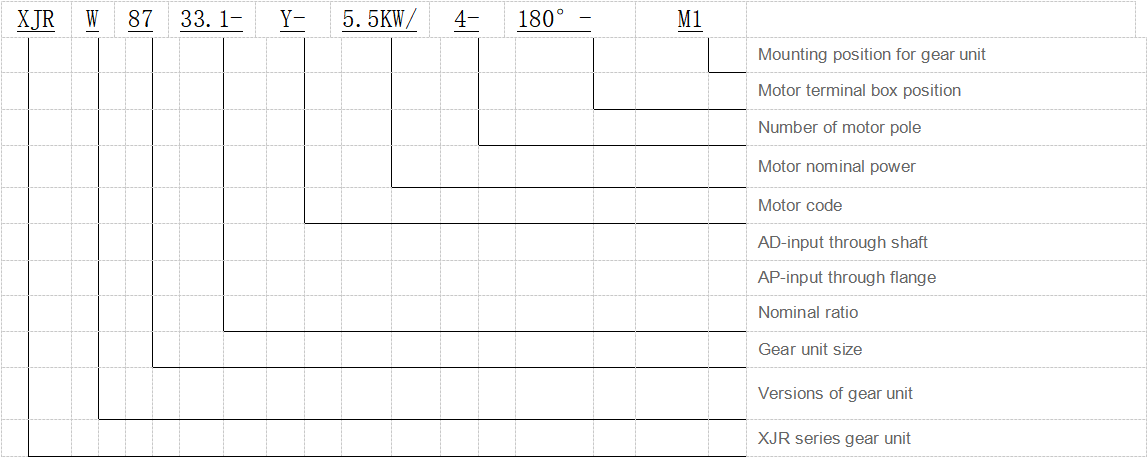

XJR helical gear hard tooth surface reducer

Product features

(1) XJR series coaxial helical gear reducers are manufactured in combination with international technical requirements, and have high scientific and technological content.

(2) The gear has the design of quick demonization, and the fuselage is driven by helical gears.

(3) Compared with other motors, the working efficiency is higher, the tooth surface is finely ground, the noise is low, the structure is compact, the design is exquisite, and the installation methods are diverse.

(4) It can be assembled and installed in various directions according to the requirements, and has various combined structural forms, which can meet the needs of users for various transmission conditions.

Specification parameters

Installation form: base type, flange type, small flange type and torsion arm type.

Output mode: solid shaft Input mode: directly connected motor, shaft input and connecting flange input. Technical parameters: speed ratio I = 5 ~ 264, XJR/XJR combination can reach 18125.

Efficiency: Grade II 96%, Grade III 94%, XJR/XJR combination 85%.

Working principle

The working principle of the helical gear hard tooth surface reducer is as follows: Helical gear: Helical gear is one of the most important components of the reducer. Its tooth surface is beveled at a certain angle, usually a bevel angle, to the direction of the input shaft. As the input shaft rotates, the helical gear turns along its axis and transfers force to the output shaft. Input Shaft: The input shaft transfers power to the helical gear, causing it to start rotating. The input shaft is usually connected to an electric motor or other power source. Output shaft: The output shaft is the shaft that outputs power from the reducer. When the helical gear turns, it turns the output shaft and reduces the speed while increasing the torque. Hardened tooth surface: The tooth surface of the helical gear is hardened to give it high hardness and wear resistance. Hard tooth surfaces can significantly improve the life and reliability of the reducer and reduce gear wear and damage. Reduction ratio: The number of teeth of the helical gear and the gear size determine the reduction ratio. The reduction ratio represents the ratio between the input shaft revolutions and the output shaft revolutions. It determines the speed and torque of the output shaft. According to different application requirements, different reduction ratios can be selected. The working process of the helical gear hardened surface reducer is that the input shaft transmits power to the helical gear. After the helical gear rotates, it is transmitted to the output shaft through the gear, so that the output shaft reaches the required speed and torque. Because helical gear hardened surface reducers have the characteristics of high efficiency, low noise and durability, they are widely used in various mechanical transmission systems