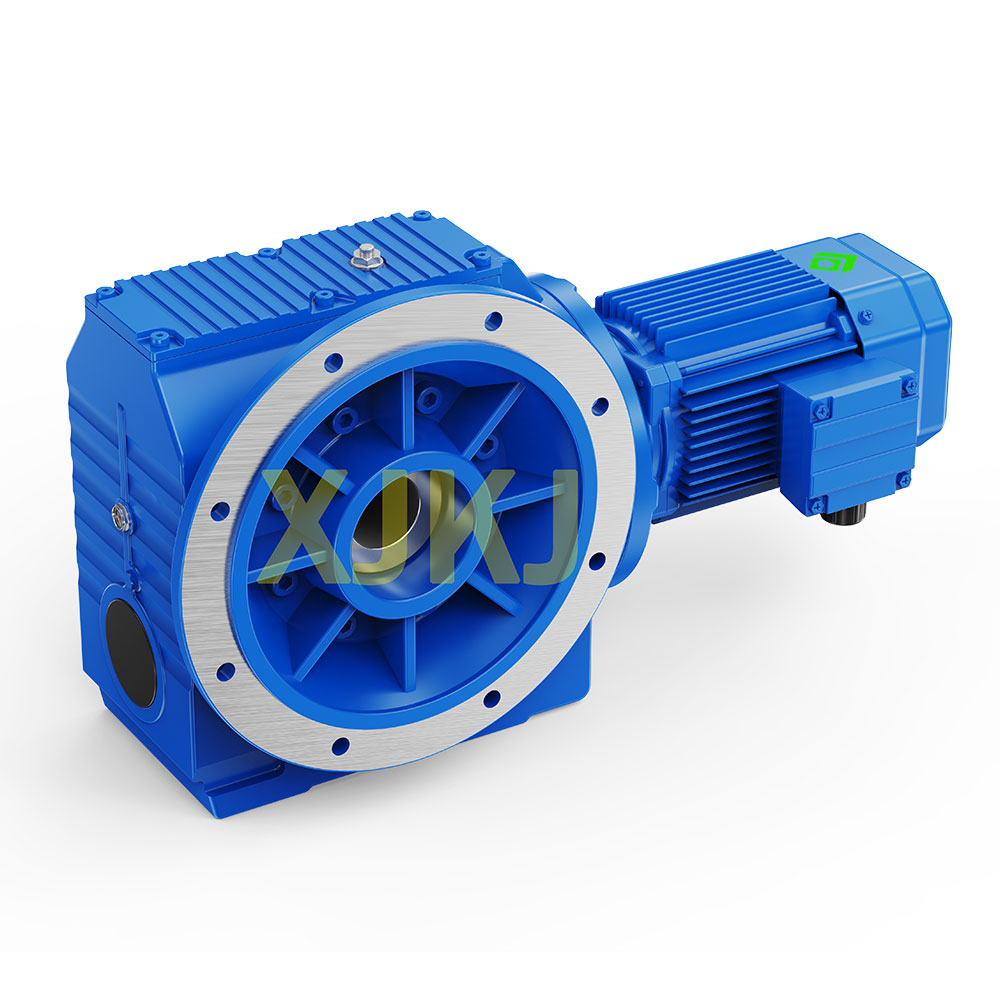

XJS series helical gear worm reducer

Product features

(1)XJS series helical gear worm reduction motor has high technology content, and the helical gear is combined with worm gear to drive integrally, which improves the torque and efficiency of the motor. This series of products have complete specifications, wide speed range, good versatility, suitable for various installation methods, safe and reliable performance and long service life, and have implemented the requirements of international standards.

(2) The concave and convex surface of the machine body has the function of heat dissipation, strong vibration absorption, low temperature rise, low noise, large transmission ratio, stable operation and compact structure.

(3) The machine has good sealing performance and strong adaptability to the working environment.

(4) The machine has high transmission precision, which is especially suitable for working in occasions with frequent starting. It can be connected with various reducers and equipped with various motor drives, and can be installed at the 90-degree transmission operation position.

(5) The key parts of the motor are made of high wear-resistant materials and have undergone special heat treatment, which has the characteristics of high machining accuracy, stable transmission, small volume, large bearing capacity and long service life.

(6) The reducer can be equipped with all kinds of motors, which forms the mechatronics, and completely ensures the quality characteristics of products.

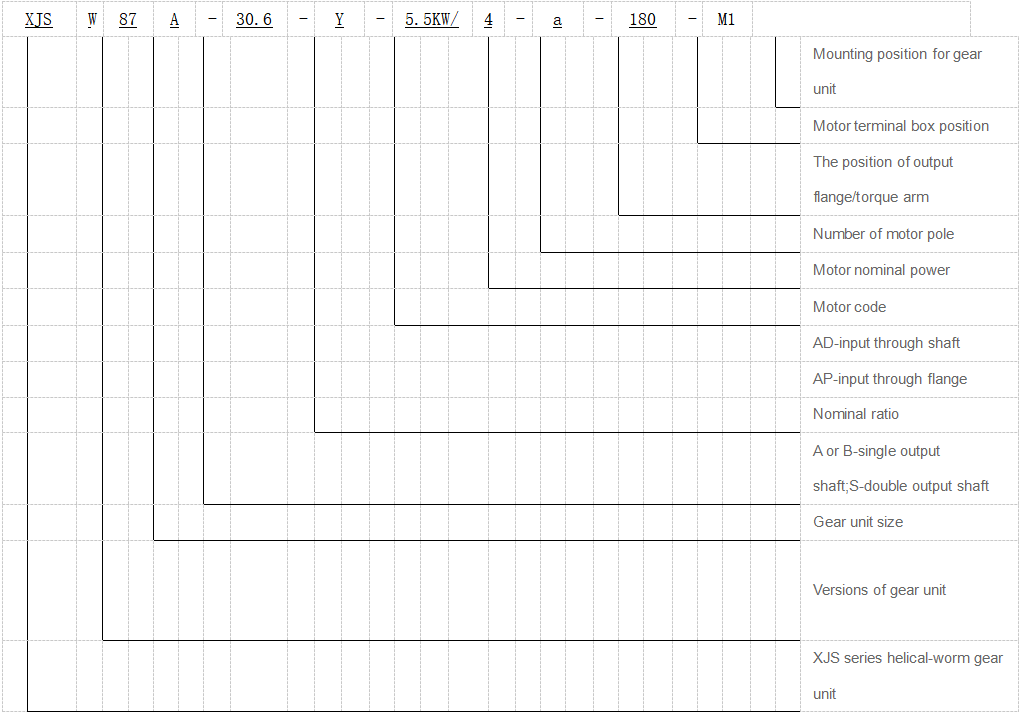

Specification parameters

Installation form: base type, flange type, small flange type and torsion arm type.

Output mode: solid shaft, hollow shaft, locking disc hollow shaft and involute spline hollow output shaft.

Input mode: directly connected motor, shaft input and connecting flange input.

Technical parameters: speed ratio I = 23.8 ~ 389, and XJS/XJR combination can reach 26688.

Efficiency: speed ratio I = 23.8 ~ 67.8, 77%; Speed ratio I 73.7 ~389, 62%; XJS/XJR combination 57%

Working principle

Transmission shaft: The transmission shaft of the helical gear worm reducer is equipped with a transmission helical gear. When the driving shaft rotates, the driving bevel gear and the worm gear mesh with each other to transmit power. Worm gear transmission: Worm gear consists of worm gear and worm gear. When the worm wheel rotates, the thread cutting action of the worm will push the worm wheel tooth surface to rotate. Because the worm wheel has fewer teeth and larger pitch, the worm wheel rotates slowly, resulting in a deceleration effect. Deceleration effect: due to the special structure of worm gear meshing transmission, a larger transmission ratio can be realized, thus achieving the deceleration effect. Through the transmission of the helical gear worm reducer, the high-speed rotation of the driving shaft is converted into the low-speed and high-torque output of the driven shaft. Stability and silence: The bevel gear worm reducer has a large contact area and good transmission stability because of the bevel cutting of the worm gear and the continuous contact with the worm gear tooth surface. At the same time, it can effectively reduce noise and vibration, and the operation is relatively stable. Through the above principle, the helical gear worm reducer can realize the effect of high-speed rotation of the driving shaft to low-speed and high-torque output of the driven shaft. It has the advantages of simple structure, high transmission efficiency and strong bearing capacity, and is widely used in machinery manufacturing, conveying equipment, automation and other fields.